Features of maize flour mill line:

1. Dry milling technology save labor work.

2. Fully atomatic with high performance.

3. Easy operation and mantainence and energy saving.

4. High output rate of final products.

5. Installation, staff training service.

6. Reasonable price.

This is the commercial maize flour milling processing machine,It include:

Cleaning-- conditioning-- degerminating--milling--sifting-- packing

1. Cleaning system: when buying the maize, normally the maize is very dirty in Africa countries. So before processing, need to cleaning first.In the maize there is many kind of impurity, like stone, iron, rope, plastic etc. So according this we use maize drum sifter/maize cleaner/maize destoner etc machines to cleaning the maize.

2. Degerminating system: After cleaning the maize, before degerminating, first need the moisture the maize and let the maize sleep in the moisture bin for 2-10 hours according the different request, then go to the maize degerminator, the degerminator can scrub the maize skin from maize kernel and dislodge the germ from its cavity with the minimum reduction in size of broken fragments.

3. Milling system: The process of manufacturing the products involves three fundamental sub-processes. Firstly, physically detaches the three components of the maize kernel from each other with as little dilution or mixing as possible. Secondly, sorts and classifies the detached particles into specific groups and the last, sizes and reduces the particles to the required granularity. The three components are then recombined as necessary depending on the type of finished product required. The aim of the process then, is to detach the bran and germ from the maize kernels with a minimum disintegration of either the endosperm or the bran/ germ casing. The pure endosperm is then gradually reduced in size to form products of different granularity, ranging from the relatively large pieces of samp to the very Fine maize flour.

4. Packing system: Maize flour packaging machine can packing with different kind of bags, like 1kg/2kg/5kg/10kg/25kg/50kg.

Features of maize flour mill line:

1. Dry milling technology save labor work.

2. Fully atomatic with high performance.

3. Easy operation and mantainence and energy saving.

4. High output rate of final products.

5. Installation, staff training service.

6. Reasonable price.

This is the commercial maize flour milling processing machine,It include:

Cleaning-- conditioning-- degerminating--milling--sifting-- packing

1. Cleaning system: when buying the maize, normally the maize is very dirty in Africa countries. So before processing, need to cleaning first.In the maize there is many kind of impurity, like stone, iron, rope, plastic etc. So according this we use maize drum sifter/maize cleaner/maize destoner etc machines to cleaning the maize.

2. Degerminating system: After cleaning the maize, before degerminating, first need the moisture the maize and let the maize sleep in the moisture bin for 2-10 hours according the different request, then go to the maize degerminator, the degerminator can scrub the maize skin from maize kernel and dislodge the germ from its cavity with the minimum reduction in size of broken fragments.

3. Milling system: The process of manufacturing the products involves three fundamental sub-processes. Firstly, physically detaches the three components of the maize kernel from each other with as little dilution or mixing as possible. Secondly, sorts and classifies the detached particles into specific groups and the last, sizes and reduces the particles to the required granularity. The three components are then recombined as necessary depending on the type of finished product required. The aim of the process then, is to detach the bran and germ from the maize kernels with a minimum disintegration of either the endosperm or the bran/ germ casing. The pure endosperm is then gradually reduced in size to form products of different granularity, ranging from the relatively large pieces of samp to the very Fine maize flour.

4. Packing system: Maize flour packaging machine can packing with different kind of bags, like 1kg/2kg/5kg/10kg/25kg/50kg.

PROFESSIONAL MANUFACTURER---MAIZE MILL/WHEAT MILL

WhatsApp: +86 1367 3181 716 Email: helen@hdfmill.com

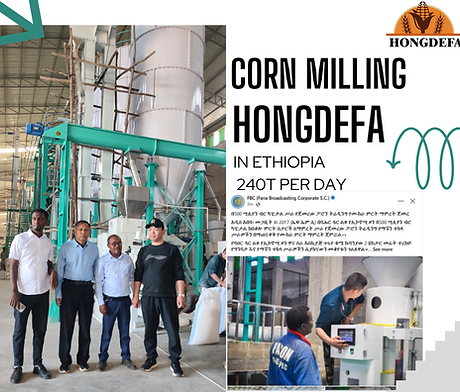

Hongdefa Mill Project in Angola

A large-scale corn processing solution tailored for the Angolan market, with a daily processing capacity of 240 tons, adapting to local raw material characteristics and market demand.

Project Highlights

-

Adopts a localized adaptation design to cope with power grid conditions such as local voltage fluctuations, ensuring strong operational stability.

-

The production line has a high degree of automation, requiring only a small number of operators to complete the entire process, reducing labor costs.

-

The finished corn flour has uniform quality, meeting local food safety standards and enjoying high market recognition.

Used For Ugali,Pirao,and so on

Make FUBA

250 T/ 24H MAIZE FLOUR MILL

The principple of the technological designing:To choose the equipments should be guarantee the demand of the craft function and various product quality, it is consisted by most advanced cleaning machine of China.

The technological design is reasonable and adjusts vivid, strong adaptability,advance equipments, high automation degree, credibility function, economy and practicality, good cleaing part.

Choose the most popular dry cleaning methods to process the corn to produce non-pollution corn flour. The stability of the machines is strong, the function is credibility, economy and practicality, the quality of the corn flour is stable, index is forerunner

This is the commercial maize flour milling processing machine,It include:

Cleaning-- conditioning-- degerminating--milling--sifting-- packing

1. Cleaning system: when buying the maize, normally the maize is very dirty in Africa countries. So before processing, need to cleaning first.In the maize there is many kind of impurity, like stone, iron, rope, plastic etc. So according this we use maize drum sifter/maize cleaner/maize destoner etc machines to cleaning the maize.

2. Degerminating system: After cleaning the maize, before degerminating, first need the moisture the maize and let the maize sleep in the moisture bin for 2-10 hours according the different request, then go to the maize degerminator, the degerminator can scrub the maize skin from maize kernel and dislodge the germ from its cavity with the minimum reduction in size of broken fragments.

3. Milling system: The process of manufacturing the products involves three fundamental sub-processes. Firstly, physically detaches the three components of the maize kernel from each other with as little dilution or mixing as possible. Secondly, sorts and classifies the detached particles into specific groups and the last, sizes and reduces the particles to the required granularity. The three components are then recombined as necessary depending on the type of finished product required. The aim of the process then, is to detach the bran and germ from the maize kernels with a minimum disintegration of either the endosperm or the bran/ germ casing. The pure endosperm is then gradually reduced in size to form products of different granularity, ranging from the relatively large pieces of samp to the very Fine maize flour.

4. Packing system: Maize flour packaging machine can packing with different kind of bags, like 1kg/2kg/5kg/10kg/25kg/50kg.

We will design the machine depend on local condition: land size, specification of finished product.

-

Features of Maize Grinding Machine:

-

1. Turnkey project of maize grinder machine.

-

2. Advanced technology support and customized design.

-

3. Thorough crafts and rational allocation.

-

4. Low power consumption.

-

5. Perfect after-sales service.

-

6. Two year guarantee.

Hongdefa Projects

Why Choose Hongdefa?

Company Introduction

Shijiazhuang Hongdefa Machinery Co., Ltd. is a high-tech enterprise, specializing in the design, manufacture, sales, installation, and commissioning of complete sets of grain storage and processing

projects, as well as after-sales service. Our company mainly focuses on wheat processing equipment and maize processing equipment, with European technology, South African maize processing, and Chinese wheat processing. We roll out unique and innovative wheat flour mills and maize mill plants.

Shijiazhuang Hongdefa Machinery Co., Ltd.'s head office is located in Shijiazhuang, about one hour by high-speed rail from Beijing and a three-hour flight from Guangzhou. We have approximately 100 employees, a manufacturing facility of 30,000 square meters, and 1,000 square meters of office space.We have more than 40 years of experience in the flour milling market.

Contact Me

Add:Zanhuang,Shijiazhuang, Hebei, China

E-mail: helen@hdfmill.com

Mob/ Whats App (24h):+86 13673181716